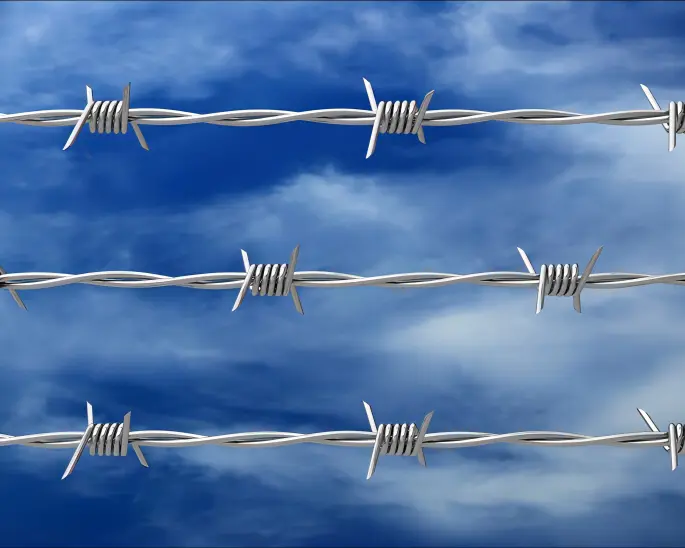

Double Wire Reverse Twist Hot Dip Galvanized Barbed Wire 2mm Wire 50m Long

products specification

| Material | Mild steel |

| Finish | Hot Dipped Galvanized |

| Wire Construction | Double Stranded Wire |

| Length/Roll | 100m/150m/Roll or customized |

| Main Wire Diameter (Gauge) | 2.2mm(standard)/2.5mm/2.8mm |

| Barb Spacing | 10.2cm |

| Colour | Grey |

| Weight/roll | 10KG/15KG |

| Dimension/Roll with 100 meters | 25cm*25cm*30cm |

| Dimension/Roll with 150 meters | 30cm x 30cm x 30cm |

| Accurate Zinc Coating | Yes |

Features

1. 4-Point Sharp Spikes

Our barbed wire is made of thick, double-stranded hot-dip galvanized steel wire. The 4-point sharp barbs are evenly spaced every 10 cm, with each spike measuring about 4 cm in length. The surface is corrosion-resistant, making it highly durable and stable even in harsh weather conditions. With superior strength and rust protection, it offers a long service life of more than 20 years.

2. Hot-dip galvanized barbed wire

Manufactured from premium hot-dip galvanized steel, this barbed wire provides exceptional resistance to rust and corrosion. It has high tensile strength and excellent break resistance, ensuring long-term stability and security. Ideal for fencing applications, it delivers reliable protection and durability under outdoor exposure.

3. DIY Customization

Lightweight and flexible, this barbed wire roll is easy to bend and shape, making it suitable for both functional and decorative purposes. In addition to fencing, it can be used for a variety of creative projects such as crafts, art installations, frames, jewelry, furniture accents, wreaths, and lighting designs. Available in 100 m, 150 m, and 200 m coils to meet different needs.

Application

Ideal for farms, gardens, and courtyards, this barbed wire fence provides reliable protection for your property, plants, and trees. It can also be used to repair damaged fences. With its strong deterrent effect, it helps keep trespassers and wild animals away, ensuring safety and peace of mind.

Installation on Barbed Wire

Step 1:

Wear safety goggles, rubber gloves, boots, and protective clothing. Work with a partner for safer and easier installation.

Step 2:

Set posts about 2 meters apart. Bury one-third of each post below ground and secure it firmly with concrete before attaching the wire.

Step 3:

Mark each wire’s position on the posts. Also mark the middle posts at the same height as the start and corner posts for easier alignment.

Step 4:

Attach the first wire at the bottom of the starting post. Wrap and twist it around the post 4–5 times to secure tension, then carefully unroll it toward the corner or end post.

Step 5:

Secure the netting to the posts using iron wire or special fasteners. Make sure the netting is smooth and tight, and check all connections to ensure they are firm and secure.