Concertina Electric Galvanized Razor Barbed Wire

products specification

Concertina razor wire Application

Prisons

Military Facilities

Electrical substations or high voltage pylons

Railway yards

Airports, Country Borders

Factories and warehouses, Highways, Private residences

Hazardous chemical plants or storage areas

Features

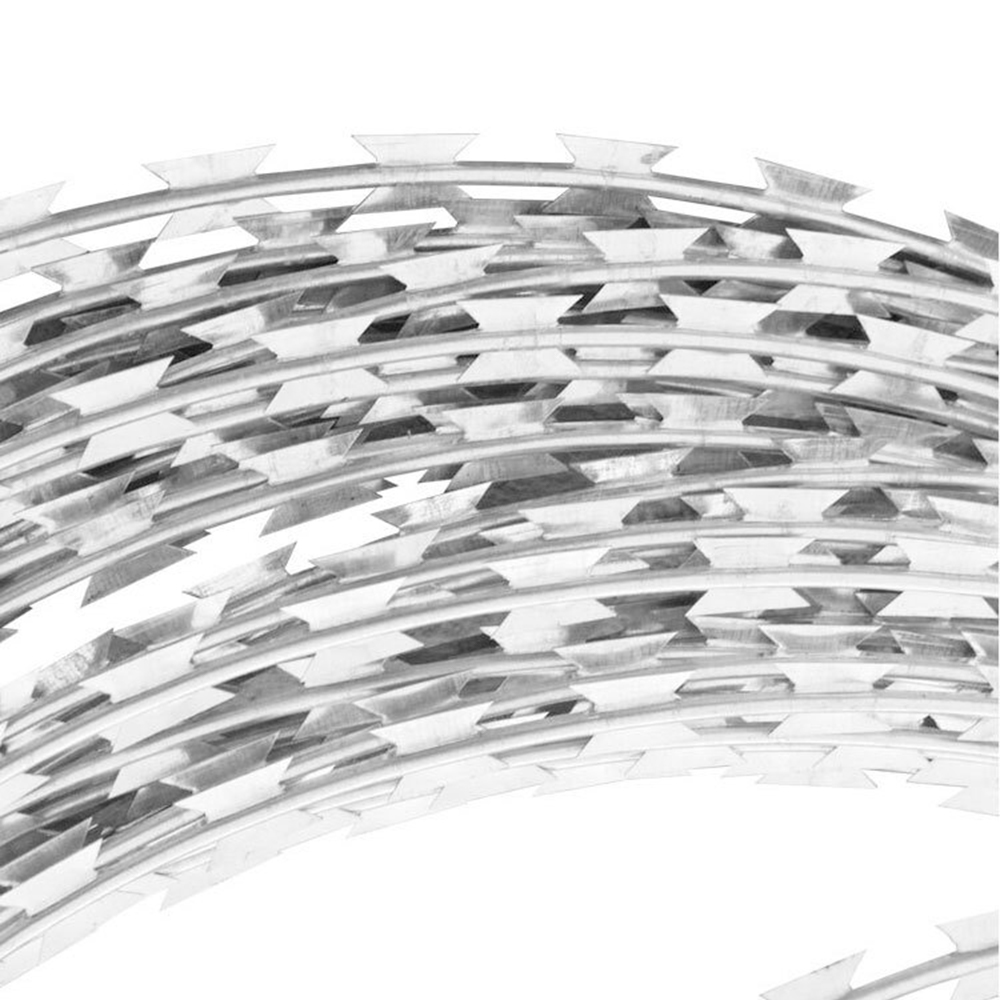

1.The top-quality hot-dip galvanized razor wires ensures high strength, Double helical blade barbed wire, with dense spacing, greatly improves the protection time of wire mesh, easy to install, Long service life up to 15 years above.

2.Durable low-carbon steel wire, strong support, strong tensile strength, adopts high-temperature hot-dip galvanizing processes to effectively solve problems such as rust and cracking of products.

3.Various blade types and installation options provide sufficient deterrence and anti- climbing performance,Wear resistance,it is installed on walls or around the top of your garden fence for added security. This razor wire, suitable for all types of outdoor use, will be a perfect choice for protecting your garden or commercial property.

4.Concertina Razor Wire-Galvanized Steel/Stainless Steel, BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30, CBT-65, CBT-60 used for Prison, Border Security.

Concertina Razor Wire Material types

√ Hot-Dip Galvanized Razor Wire:

This is the most popular material option with the best cost-effective – it is second in terms of durability and corrosion resistance, though slightly inferior to stainless steel materials, its cost is much lower than that of stainless steel. If you are not sure how to select, hot-dip galvanized razor wire is suitable for various projects.

√ PVC Coated Razor Wire

The most aesthetically pleasing material option, It involves applying a layer of polyvinyl chloride (PVC) over galvanized steel, providing dual-layer protection. This coating not only offers additional corrosion resistance but also comes in a variety of colors, However, the cost is also higher than that of hot dipped galvanized. If you have simultaneous demands for durability and aesthetics, then you can choose PVC coated razor wire.

√ Stainless Steel Razor Wire

The top-level material option for razor wire, it is the most durable of all materials. It never rust in marine, saline-alkali, or humid areas, making it very suitable for harsh environments. However, it is also the most expensive of all materials. If you are not concerned about cost and only pursue longevity, then we recommend choosing stainless steel razor wire.

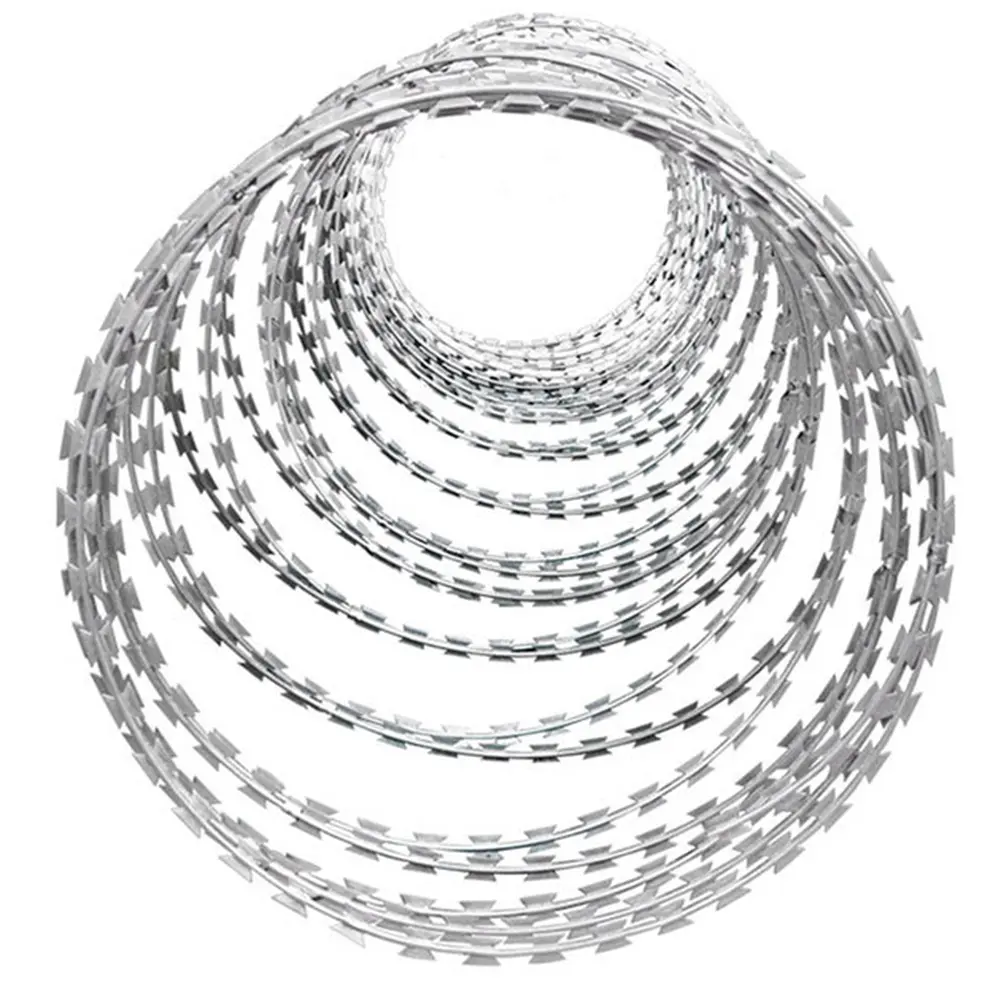

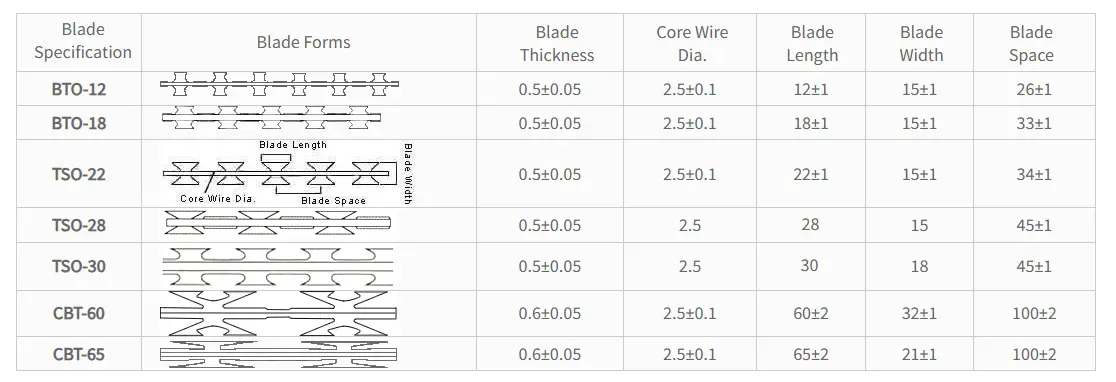

Blade Models Selection

Here we offer razor wire with various blade models by specific security needs and your budget:

• BTO-10: Suitable for location with low security requirements, low cost, and easy to install.

• BTO-18: Suitable for location with medium security requirements, providing medium protection.

• BTO-22: Suitable for location with high security requirements, offering good protection and strong deterrent effect.

• BTO-30: Suitable for location with the highest security requirements, providing the strongest protection.

• CBT-60 and CBT-65: Suitable for location with extremely high security requirements, such as military and government facilities, offering the highest level of protection and deterrent effect.