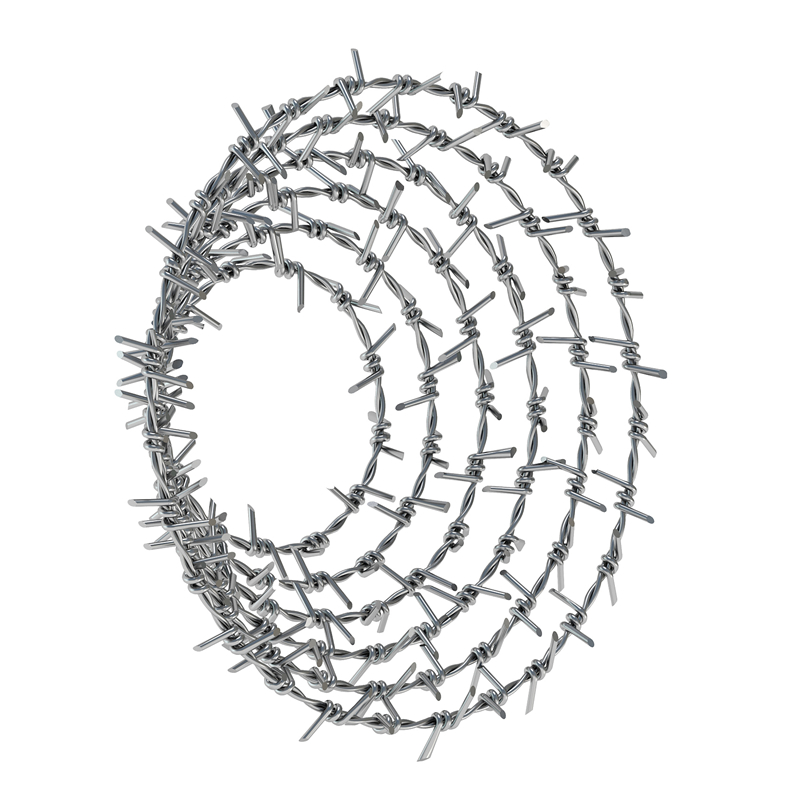

Best Selling Barbed Wire Hot Dipped Galvanized(LF-BW)

Product Description

products specification

| Material | Mild steel |

| Finish | Hot Dipped Galvanized |

| Wire Construction | Double Stranded Wire |

| Length/Roll | 100m/150m/Roll or customized |

| Main Wire Diameter (Gauge) | 2.2mm(standard)/2.5mm/2.8mm |

| Barb Spacing | 10.2cm |

| Colour | Grey |

| Weight/roll | 10KG/15KG |

| Dimension/Roll with 100 meters | 25cm*25cm*30cm |

| Dimension/Roll with 150 meters | 30cm x 30cm x 30cm |

| Accurate Zinc Coating | Yes |

Features

Application

This product is highly corrosion-resistant, weather-resistant, UV-resistant, and aging-resistant, making it an ideal solution for barrier protection across a wide range of applications. It is commonly used to secure grassland boundaries, railways, highways, and key facilities such as warehouses and prisons. Its versatile design allows flexible installation in spiral, linear, or flat configurations and can be combined with accessories like razor barbed wire to form a multi-layered security system. Easy to install, cost-effective, and practical, it provides a strong visual deterrent while ensuring reliable protection. Widely applied in industrial, agricultural, livestock, transportation, and forest protection settings, this product offers a durable and efficient solution for safety and security needs.

Installation on Barbed Wire