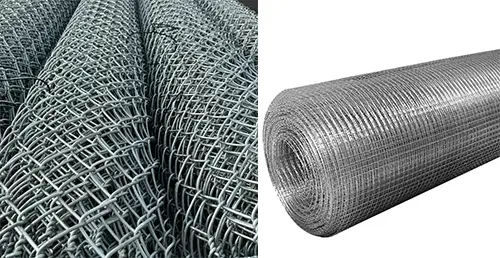

What Is Welded Wire Mesh?

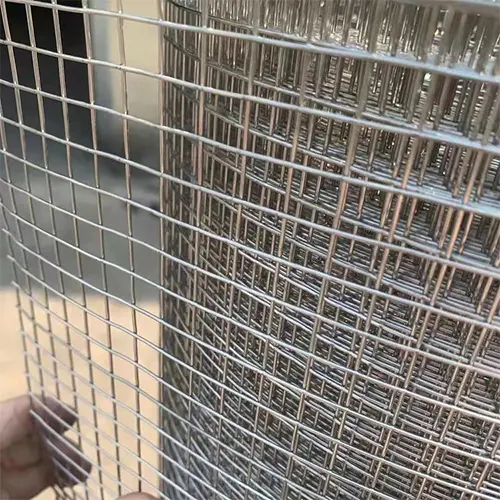

Welded wire mesh is one of the most practical and versatile wire products used across construction, industry, agriculture, and infrastructure projects. It consists of a grid of parallel longitudinal wires welded together at their intersections with equal spacing, forming a strong and uniform mesh structure.

Unlike woven mesh, where the wires are interlaced, welded wire mesh is made by electric resistance welding. This process fuses the wires at every crossing point, creating a rigid, dimensionally stable panel or roll that maintains its shape even under pressure.

Manufacturing Process

The production of welded wire mesh begins with selecting high-quality low-carbon steel wire or stainless steel wire. These wires are straightened, cut to the desired length, and fed into automatic welding machines. At each intersection, the machine applies precise electrical current and pressure, welding the wires together permanently.

After welding, the mesh is treated for corrosion protection. Common surface finishes include:

•Hot-dip galvanizing – a thick zinc coating that resists rust in outdoor or marine environments.

•Electro-galvanizing – a lighter, smoother finish ideal for indoor or temporary applications.

•PVC coating – a layer of polyvinyl chloride that enhances durability and provides aesthetic color options.

Common Specifications

Welded wire mesh is available in many mesh openings, wire diameters, and formats.

Typical configurations include:

•Mesh openings: from 6.4 mm × 6.4 mm up to 150 mm × 150 mm

•Wire diameters: from 0.5 mm to 6 mm

•Panel sizes: 1 × 2 m, 1.2 × 2.4 m, or customized

•Rolls: 0.9 m, 1.2 m, or 1.5 m high, 30 m long

The mesh can be easily cut, bent, or shaped, making it adaptable to both structural and decorative applications.

Applications

Because of its strength and clean appearance, welded wire mesh is widely used in:

•Construction: concrete reinforcement, formwork panels, and partition barriers.

•Fencing: residential, industrial, and highway security fencing.

•Industrial use: machine guards, shelving, and storage cages.

•Agriculture: animal enclosures, crop protection, and greenhouse panels.

•Infrastructure: retaining walls, bridge decks, and tunnel reinforcement.

In modern projects, galvanized and PVC-coated mesh panels are also used for fencing systems that need both durability and aesthetic appeal.

Advantages

•High strength and rigidity – resists deformation and bending.

•Long service life – corrosion-resistant coatings for outdoor use.

•Quick installation – easy to cut, fasten, and position.

•Uniform mesh openings – ensures consistent spacing and reinforcement.

•Customizable options – various wire diameters, materials, and finishes.

Material Choices

Depending on project requirements and exposure environment:

•Mild steel for low-cost indoor uses.

•Hot-dip galvanized steel for general outdoor conditions.

•Stainless steel where long-term corrosion resistance is essential.

•PVC-coated mesh for color matching and additional protection.

Whether used to reinforce concrete, secure a boundary, or protect equipment, welded wire mesh delivers a balance of strength, flexibility, and durability that few materials can match. It's one of those simple, engineered products that quietly support countless modern structures and spaces — reliable, adaptable, and built to last.