Galvanized Steel Wire vs. PVC-Coated Steel Wire: How to Choose the Best Tension Wire for Your Project

In projects such as construction, horticulture, and agriculture, the choice of tension wire directly affects the durability and functionality of the project. Galvanized steel wire and PVC-coated steel wire are two mainstream options, each with its unique advantages. This article will conduct a comparative analysis of their characteristics to help you make the optimal decision.

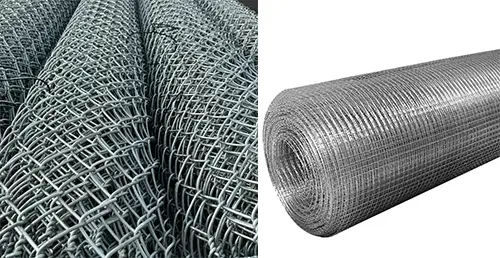

Galvanized Steel Wire: Industrial - grade Rust Protection and High Load - bearing Capacity

In projects such as construction, horticulture and agriculture, the choice of tension wire directly affects the durability and functionality of the project. Galvanized steel wire and PVC-coated steel wire are two mainstream options, each with its unique advantages. This article will conduct a comparative analysis of their characteristics to help you make the optimal decision.

Galvanized Steel Wire: Industrial-Grade Rust Protection and High Load-Bearing Capacity

1.Excellent Rust Resistance Through the hot - dip galvanizing process, galvanized steel wire forms a dense zinc layer on the surface of the wire. This layer can effectively isolate oxygen and moisture, preventing metal oxidation. In ordinary outdoor environments, its rust - proof lifespan can reach 10 - 15 years, making it particularly suitable for dry or windy areas.

2.High Load - Bearing Capacity and Rigid Structure Galvanized steel wire retains the natural advantages of metal materials. Its tensile strength is usually 350 - 500MPa, making it suitable for scenarios that require high load - bearing capacity, such as building support structures, heavy - duty fences, or vineyard trellises.

3. Economy and Wide Applicability Compared with PVC - coated products, galvanized steel wire has a lower cost and does not require complex maintenance. Its metallic texture and industrial - style design are suitable for scenes such as farms and warehouses. It is an ideal choice for projects that prioritize practicality.

PVC-Coated Steel Wire: All-Weather Protection and Aesthetic Appeal

1.Double Corrosion Protection The PVC-coated steel wire is wrapped with a layer of polyvinyl chloride (PVC) plastic outside the galvanized layer, forming a dual physical and chemical protection. Even if it is exposed to high - salt coastal environments or acid rain for a long time, it can resist corrosion, and its service life can be extended to more than 20 years.

2.Diverse Colors and Safety The PVC layer offers a rich selection of colors (such as green, black, brown), which can perfectly blend into landscape designs of gardens, courtyards, etc. The surface is smooth without burrs, avoiding scratches, making it suitable for children's activity areas or pet fences.

3.Noise Reduction and Impact Resistance The PVC coating can buffer the noise generated by metal collisions and reduce vibrations in windy weather. Its flexibility also reduces the risk of wire breakage, making it suitable for greenhouse sheds or sunshade net supports that require high stability.

Comparative Decision-making: Precise Matching Based on Requirements

|

Comparison Dimensions |

||

|

Applicable Environments |

Ordinary outdoor areas, dry regions |

High - humidity areas, coastal areas, chemically - polluted regions |

|

Load - bearing Requirements |

High strength (400 kg/m) |

Medium - high strength (200 - 400 kg/m) |

|

Aesthetic Requirements |

Industrial style, concealed installation |

Landscape design, color matching |

|

Budget Costs |

Low (saving 30% - 50%) |

Relatively high (with additional PVC process costs) |

|

Maintenance Frequency |

Inspect the wear of the zinc layer every 5 - 8 years |

Almost maintenance - free |

Conclusion: How to Select the Optimal Tension Wire?

Conclusion: Prioritize galvanized steel wire if your project has a limited budget, high load - bearing requirements, or is located in an inland dry environment (such as ranch fences, warehouse reinforcement).

Prioritize PVC - coated steel wire if your project requires long - term anti - corrosion, aesthetic design, or is located in a humid/coastal area (such as fences for beachfront villas, ecological park facilities).

Composite solution: For extreme environments (such as chemical plants), you can choose the "galvanized + PVC" double - layer protected steel wire, which combines strength and durability.

By clarifying the geographical conditions, functional requirements, and aesthetic standards of your project, you will be able to accurately match the type of tension wire and achieve the optimal balance between cost and performance.