Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

The world of construction and fencing is constantly evolving, and PVC Coated Welded Mesh is at the forefront. Renowned expert, John Miller, once remarked, "PVC Coated Welded Mesh is revolutionizing durability in various applications." This material proves to be more than just a protective layer; it offers strength while enhancing aesthetic appeal.

From agricultural fencing to security barriers, the versatility of PVC Coated Welded Mesh is impressive. Its weather-resistant properties ensure it withstands harsh environments. Imagine a farm where livestock roam freely, secured by this robust mesh. However, some may overlook installation details, leading to future challenges.

As industries seek reliable solutions, understanding the nuances of PVC Coated Welded Mesh becomes essential. What works for one sector might not suit another. The details matter, and reflecting on past implementations can lead to better choices in the future. Embracing this material could be a game-changer, but it requires careful consideration.

PVC coated welded mesh is widely valued for its versatile applications. This material combines durability with flexibility, making it ideal for various uses. It's often seen in fencing, providing a robust barrier against intrusions. The protective PVC layer helps resist corrosion and wear. Many prefer this mesh for residential and commercial properties.

In agriculture, PVC coated welded mesh acts as a reliable solution for enclosures. It keeps pests out while allowing airflow. Farmers appreciate its ability to withstand harsh weather conditions. However, installation can be tricky. Proper tension needs to be maintained to ensure effectiveness. Some may overlook this, leading to performance issues.

Another popular use is in industrial settings. Here, it’s used in shelving and partitions, maximizing space. The transparency of the mesh allows visibility while maintaining safety. Yet, the choice of coating color can affect heat absorption. Darker shades may retain more heat, which might not be suitable for all environments. Understanding these nuances is essential for making informed decisions.

PVC coated welded mesh is gaining popularity for its unique advantages. This type of mesh is durable and resistant to corrosion. It can withstand various weather conditions, making it suitable for outdoor applications. The PVC coating adds an extra layer of protection. This helps in extending the life of the mesh significantly. Many industries utilize this material for fencing, reinforcement, and safety barriers.

One notable feature is its versatility. PVC coated welded mesh comes in different widths and sizes. This allows for customization to fit specific needs. It is not just functional, but also aesthetically pleasing. The colorful coatings can match different environments, enhancing visual appeal. However, some may find the initial cost higher compared to traditional options. It's essential to weigh immediate costs against long-term savings.

Another consideration is installation. While PVC coated mesh is relatively easy to install, mistakes during the process can occur. Proper tools and techniques are crucial. A poorly installed mesh can lead to further expenses down the line. Users must be meticulous. The benefits are clear, but attention to detail remains important.

PVC coated welded mesh has found a significant place in various industries. Its versatility and durability make it an ideal choice for many applications. According to a recent market report, the global welded mesh market is expected to grow at a CAGR of 5.3% from 2021 to 2026. This growth highlights its importance across several sectors.

In the agricultural industry, PVC coated welded mesh is commonly used for animal enclosures and fencing. It provides a robust barrier against pests and predators. Reports indicate that up to 15% of livestock losses can occur due to inadequate fencing. This reinforces the necessity for reliable solutions like PVC coated welds, which offer both protection and visibility.

The construction sector is another major user. Builders utilize PVC coated welded mesh for concrete reinforcement. This mesh increases the strength and durability of structures. However, some construction projects still overlook its benefits. Over 20% of projects lack adequate material specifications, leading to structural vulnerabilities. Proper education on the advantages of using PVC coated welded mesh can help mitigate these issues.

When installing PVC coated welded mesh, preparation is key. Begin by ensuring the ground is level and free from debris. This step can save time and effort later on. If the surface is uneven, consider adding gravel or soil. Make certain the mesh will lie flat.

Attach the mesh securely using stainless steel fasteners. These resist rust and ensure durability. If you use weak materials, the mesh may fail over time. Check your work frequently to ensure tight connections. Loose areas can lead to structural issues.

Tips: Always wear gloves when handling the mesh. The edges can be sharp. It's crucial to avoid injury. Mark your installation points clearly to maintain accuracy. Mistakes made in positioning can lead to wasted materials and time. If you make an error, learn from it. Adjust your plan for next time.

| Use Case | Material Specifications | Installation Technique | Benefits |

|---|---|---|---|

| Security Fencing | PVC coated, 2.5mm wire | Post and Panel Method | Corrosion resistance, enhanced durability |

| Animal Enclosures | Heavy-duty 1.5mm wire | Welded Panel Installation | Safe for animals, UV resistant |

| Garden Fencing | PVC coated, 1.2mm wire | Easy Panel System | Aesthetic appeal, rust-free |

| Construction Safety | Galvanized wire with PVC coat | Temporary Fencing Setup | Portability, quick installation |

| Noise Barriers | Laminated PVC coated mesh | Fixed Installation | Sound insulation, aesthetic options |

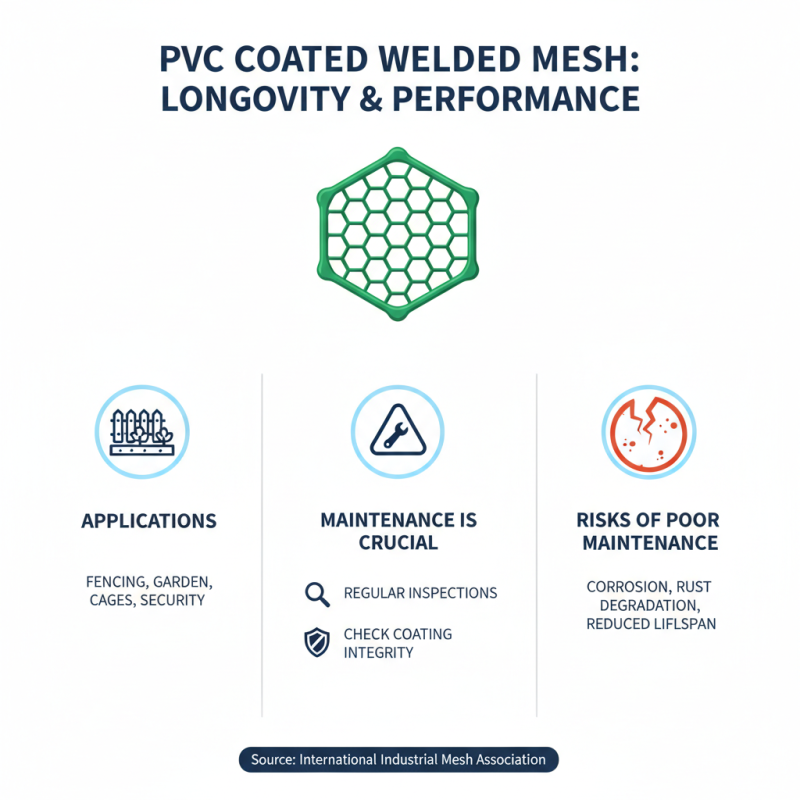

PVC coated welded mesh is widely used for various applications. However, proper maintenance is crucial for its longevity and performance. A report by the International Industrial Mesh Association indicates that poorly maintained mesh can lead to significant degradation over time. Regular inspections are essential to ensure the coating remains intact, preventing corrosion or rust from affecting the welded points.

Tips: Clean the mesh periodically with mild detergent and water. Avoid harsh chemicals that may damage the PVC coating.

Additionally, examine the mesh for any loose connections or wear. The longevity of welded mesh can be reduced by external factors like UV exposure and extreme weather conditions. Research shows that protective measures, such as applying a fresh layer of PVC, can prolong its life.

Tips: Store unused mesh indoors to prevent environmental damage. Regularly check for signs of wear, especially in high-traffic areas.

Overall, regular maintenance practices can significantly enhance the lifespan and effectiveness of PVC coated welded mesh. However, it’s essential to adopt a proactive approach and continuously monitor its condition.