Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

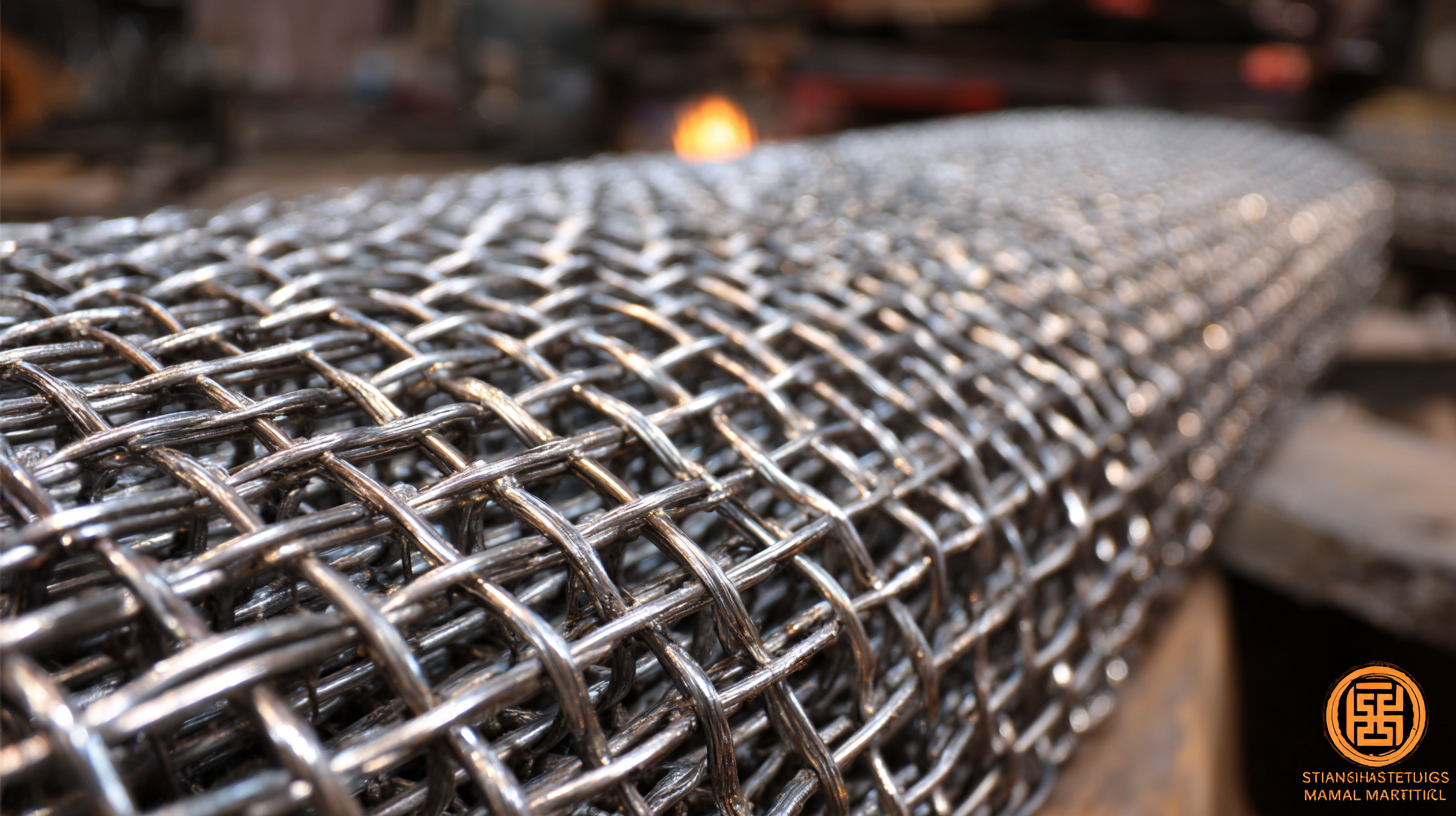

The global demand for high-quality materials continues to surge, positioning China as a premier player in the manufacturing landscape, particularly in the stainless crimped wire mesh industry. As reported by industry analysts, the stainless steel wire mesh market is expected to reach a value of $1.5 billion by 2027, growing at a CAGR of 6.2% from 2020 to 2027. This growth is driven by the expanding applications of stainless crimped wire mesh in various sectors, including construction, filtration, and industrial operations. China's robust export capabilities ensure that it meets international standards and requirements, fostering a reputation for excellence in manufacturing. This blog will delve into the exceptional qualities of Chinese-made stainless crimped wire mesh, exploring its superior strength, durability, and versatility, which make it a preferred choice across numerous industries worldwide.

Stainless crimped wire mesh is a versatile material that has found extensive applications across various industries. Its unique properties, such as corrosion resistance, durability, and high tensile strength, make it an ideal choice for different environments. In agricultural settings, stainless crimped wire mesh is commonly used for fencing and protecting crops, ensuring that animals cannot access valuable plants. In construction, it serves as a reinforcing material, providing essential support and stability for concrete structures.

When considering the use of stainless crimped wire mesh, it is important to keep a few tips in mind. First, choose the appropriate mesh size for your specific application to ensure optimal performance. Larger openings may be ideal for drainage purposes, while smaller openings can prevent debris from passing through. Additionally, always examine the quality of the mesh to guarantee long-lasting performance; high-quality stainless steel will outperform lower-grade materials in the long run.

Another advantage of stainless crimped wire mesh is its ease of maintenance. Regular cleaning with water and gentle scrubbing can help maintain its appearance and functionality. When properly cared for, this material can withstand harsh environmental conditions, making it a reliable investment for various industries in need of sturdy and versatile solutions.

In the realm of stainless crimped wire mesh, high-quality technical specifications are paramount for ensuring optimal performance across various applications. The recent advancements in the wire mesh industry, particularly in Anping County, have highlighted critical developments in stainless steel wire drawing. For instance, local manufacturers have achieved an unprecedented diameter of 0.036 mm for stainless steel wire, setting a new benchmark for the industry in China. This achievement not only showcases the capabilities of Chinese manufacturing but also addresses the long-standing "neck-stuck" issue for high-end stainless steel products.

When selecting stainless crimped wire mesh, understanding the key technical specifications is essential. Look for mesh openings and wire diameters that suit your specific application needs. A wire mesh with a finer diameter can provide improved strength and durability, making it suitable for demanding environments. Additionally, consider the wire's tensile strength and corrosion resistance, especially for applications requiring longevity under harsh conditions.

**Tips:** Always request detailed specifications and certifications from suppliers to ensure the quality of the wire mesh. Regularly consult industry reports and case studies to stay updated on the latest innovations and best practices in stainless steel manufacturing. This ensures you make well-informed decisions that align with your operational requirements.

| Specification | Value |

|---|---|

| Material Grade | AISI 304/316 |

| Wire Diameter | 1.0 mm - 6.0 mm |

| Mesh Opening | 1 mm - 50 mm |

| Weave Type | Plain, Twilled, Dutch |

| Roll Dimensions | 1m x 30m, 1.2m x 30m |

| Application | Filtration, Safety Screens, Architectural Design |

| Corrosion Resistance | Excellent |

| Tensile Strength | Up to 600 MPa |

When it comes to selecting the right stainless crimped wire mesh for your specific application, there are several key factors to consider. First, identify the purpose of the wire mesh—whether it is for filtration, safety, or aesthetic purposes. Understanding the intended use is crucial as it influences the specifications you should look for, such as mesh size, wire diameter, and material grade.

Next, evaluate the environment in which the wire mesh will be used. For outdoor applications, it’s essential to choose materials with corrosion resistance, while for indoor uses, sturdiness and fine mesh can be prioritized. Additionally, consider the regulatory standards applicable to your industry. These could dictate specific requirements for wire mesh used in various applications, ensuring safety and compliance.

By following these detailed steps, you can confidently select a stainless crimped wire mesh that meets your needs and enhances the quality of your project.

Stainless crimped wire mesh has become an essential component across various industries, showcasing its innovative applications in manufacturing. According to a recent industry report, the global demand for stainless steel wire products is projected to reach $5 billion by 2026, driven by their properties of corrosion resistance, durability, and versatility. This mesh can be found in areas such as filtration systems, architectural applications, and safety barriers, reflecting the growing preference for high-quality materials in demanding environments.

Stainless crimped wire mesh has become an essential component across various industries, showcasing its innovative applications in manufacturing. According to a recent industry report, the global demand for stainless steel wire products is projected to reach $5 billion by 2026, driven by their properties of corrosion resistance, durability, and versatility. This mesh can be found in areas such as filtration systems, architectural applications, and safety barriers, reflecting the growing preference for high-quality materials in demanding environments.

One notable application is in the food processing industry, where stainless crimped wire mesh is utilized for filtration to ensure product purity. Its ability to withstand high temperatures and harsh cleaning chemicals makes it an ideal choice. Another innovative use is in the construction sector, where the mesh provides robust reinforcement in concrete and serves as an effective safety measure on construction sites.

Tip: When selecting stainless crimped wire mesh for manufacturing applications, consider specifications such as wire diameter, mesh opening size, and material grade to ensure the best performance for your specific needs. Also, keep an eye on evolving standards in sustainability and compliance, as these factors increasingly influence material choices in manufacturing.

China has rapidly emerged as a global leader in the manufacturing and export of wire mesh products, particularly in the stainless crimped wire mesh sector. This remarkable rise can be attributed to advancements in technology, skilled labor, and a robust supply chain that allows for efficient production and distribution. The use of high-quality stainless steel materials ensures that these products not only meet international standards but also cater to diverse applications, ranging from construction to filtration systems.

Moreover, the export strength of Chinese wire mesh products is bolstered by strategic partnerships and trade agreements that facilitate market access around the world. Manufacturers are increasingly focusing on innovation and customization to meet the specific needs of their global clientele. As a result, countries across Europe, North America, and Asia are turning to Chinese suppliers for their reliability and competitive pricing. This dynamic landscape highlights China's commitment to maintaining its place at the forefront of the wire mesh industry while fostering sustainable growth in international trade.

This chart illustrates the global export strength of Chinese stainless crimped wire mesh products in comparison to other leading countries. The data reflects the export value (in million USD) over the last year.