Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

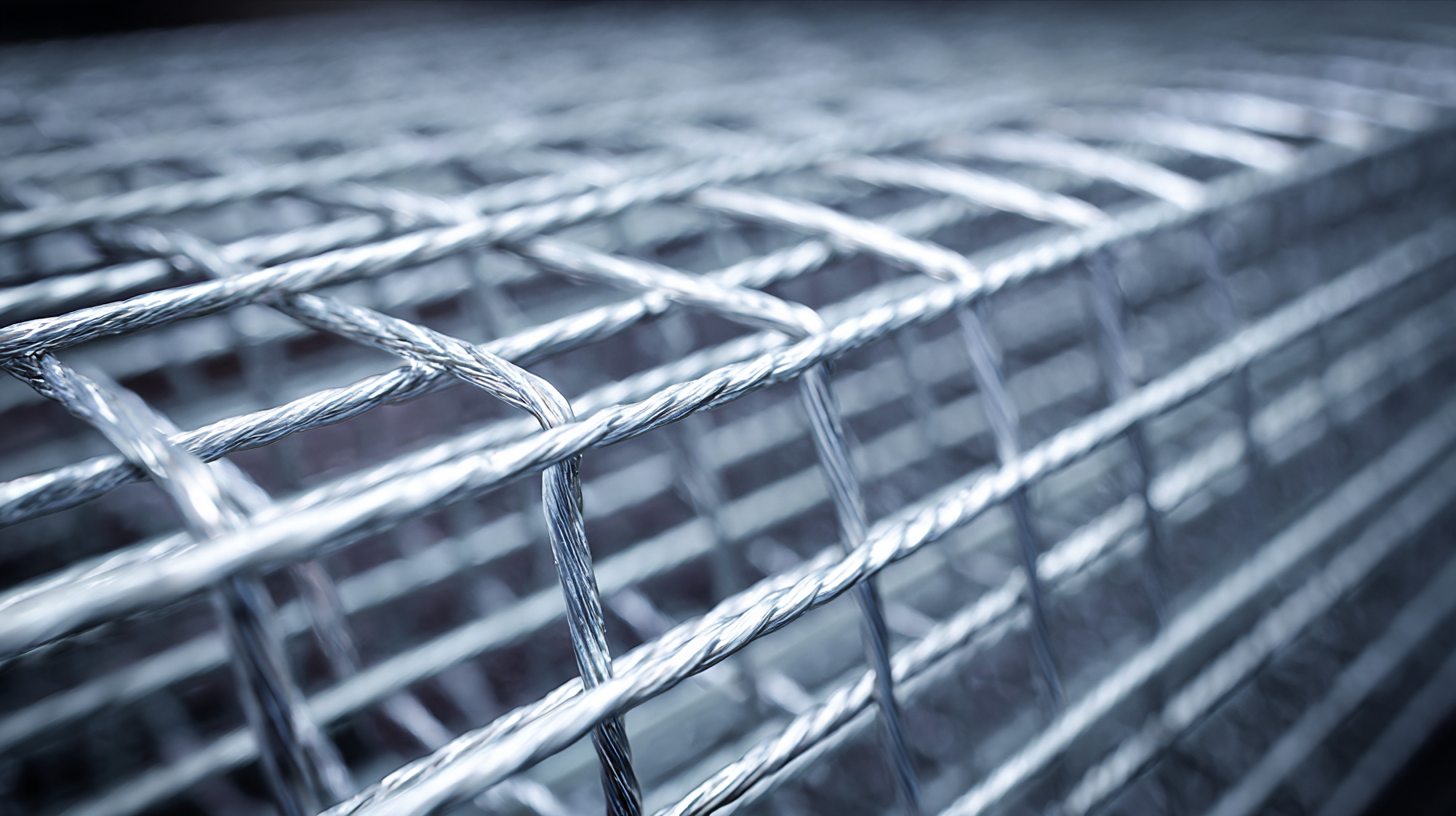

When it comes to selecting materials for your construction and fencing projects, the right choice can significantly impact both functionality and aesthetics. One material that stands out for its versatility and durability is PVC Coated Welded Mesh. This innovative product not only offers a robust framework but also provides a protective layer that resists weathering, corrosion, and wear over time. As we delve into the topic of choosing the best PVC Coated Welded Mesh for your specific needs, we will explore five essential tips that can guide your decision-making process. Whether you are fencing in a garden, reinforcing a structure, or embarking on a DIY project, understanding the key factors in selecting PVC Coated Welded Mesh will ensure that your investment pays off in longevity and performance.

Join us as we uncover the future of this vital material and how it can elevate your projects to the next level.

When selecting PVC coated welded mesh for various projects, the importance of quality cannot be overstated. High-quality PVC coated mesh not only ensures durability but also enhances the overall aesthetic and functionality of the structures. According to a report by Freedonia Group, the demand for PVC coated wire products is projected to grow at a rate of 5% annually, driven by their increasing use in construction and safety applications. Thus, understanding the factors that influence quality is essential for project success.

One critical tip for selecting the best PVC coated welded mesh is to look for products with robust corrosion resistance. This is particularly important in outdoor applications where exposure to harsh weather conditions can lead to degradation. Ensure the coating thickness meets industry standards; reports indicate that meshes with a minimum thickness of 0.3 mm offer optimal protection against wear and tear. Additionally, consider the mesh's tensile strength, which should be at least 300 N/mm² for structural integrity.

Another essential aspect is the compatibility of the mesh with specific project requirements. For instance, if the mesh is intended for agricultural use, opting for UV-stabilized PVC can prevent degradation from prolonged sun exposure. The American Society for Testing and Materials (ASTM) provides guidelines for various mesh applications that can serve as useful references. By prioritizing these quality factors, you can ensure that your PVC coated welded mesh performs effectively and lasts for years.

| Tip | Description | Importance |

|---|---|---|

| 1. Material Quality | Choose high-grade PVC material to ensure durability and resistance to environmental factors. | High-quality materials increase longevity and reduce maintenance costs. |

| 2. Coating Thickness | Opt for a thicker PVC coating for enhanced protection against corrosion and wear. | Thicker coatings extend the lifespan of the mesh in harsh conditions. |

| 3. Mesh Wire Diameter | Consider the wire diameter that suits your project's strength requirements. | Correct wire diameter ensures load-bearing capacity and structural integrity. |

| 4. Manufacturing Process | Research the manufacturing techniques used, as quality control can significantly impact performance. | Improved manufacturing processes lead to higher consistency and fewer defects. |

| 5. Supplier Reputation | Choose suppliers with a strong reputation for quality and customer service. | A reliable supplier ensures better support and guarantees product quality. |

When it comes to choosing PVC coated welded mesh, understanding the key factors that influence its durability is crucial. According to a report by the National Association of Wire Fabricators, the longevity of PVC coated products can be significantly affected by environmental conditions, coating thickness, and the quality of the base wire used. For instance, a thicker coating can offer better protection against rust and corrosion, leading to increased lifespan. This means selecting a mesh with a minimum coating thickness of 0.5mm is advisable for enduring harsher climates.

Moreover, the composition of the wire is equally important. High-quality low carbon steel is often preferred as it not only provides strength but also enhances the adhesion of the PVC coating. When evaluating options, consider products that are certified for their durability through standards such as ASTM D2247, which assesses exterior exposure to moisture and UV rays.

Moreover, the composition of the wire is equally important. High-quality low carbon steel is often preferred as it not only provides strength but also enhances the adhesion of the PVC coating. When evaluating options, consider products that are certified for their durability through standards such as ASTM D2247, which assesses exterior exposure to moisture and UV rays.

Tip: Always request samples or test pieces before finalizing your purchase to evaluate the mesh’s flexibility and strength firsthand. Additionally, consider how the mesh will be used in your project; for heavy-duty applications, opt for meshes with higher tensile strength. With proper considerations, you can ensure that your choice of PVC coated welded mesh meets the demands of your project efficiently.

When selecting PVC coated welded mesh for projects, two critical factors to examine are wire gauge and coating thickness. According to the Wire Reinforcement Institute (WRI), the wire gauge directly affects the strength and durability of the mesh. Typically, a lower gauge number indicates thicker wire, which translates to higher tensile strength. For applications requiring heavy-duty performance, such as agricultural fencing or industrial enclosures, opting for a wire gauge of 10-12 is recommended. This thickness can withstand considerable pressure and is less prone to deformation over time.

Equally important is the coating thickness. Industry reports from the International Organization for Standards (ISO) suggest that a PVC coating thickness between 0.5 mm and 1.0 mm provides optimal protection against corrosion and weathering. Thicker coatings can enhance the lifespan of the mesh, especially in harsh environmental conditions. It is crucial to choose a product that meets these standards to ensure the mesh remains functional and visually appealing for years to come. This attention to detail during the selection process will lead to higher overall project performance and sustainability.

When selecting PVC coated welded mesh for your projects, it’s crucial to strike a balance between cost-effectiveness and quality. A lower price might seem appealing, but it can often lead to compromises in material strength and lifespan. Consider how the mesh will be used; if it’s for high-stress applications, investing in higher-quality materials is advisable to avoid future expenses tied to replacements and repairs.

One essential tip is to evaluate the gauge and wire thickness of the mesh. Thicker wires generally indicate a stronger product, essential for durability and performance. Additionally, the coating's quality should not be overlooked — a thicker, more consistent PVC layer will provide better resistance to corrosion, extending the lifespan of the mesh in outdoor environments.

Another important factor is the mesh's specifications related to your project needs. Ensure the size and spacing of the openings fit your intended use to avoid over-spending on features that your project may not require. By carefully assessing these elements, you can achieve a well-balanced decision that meets both your budgetary constraints and performance expectations.

When selecting PVC coated welded mesh for your projects, the integrity of your supplier is paramount. Reputable manufacturers not only provide high-quality products but also adhere to industry standards that ensure durability and performance. According to a recent report by Grand View Research, the global market for PVC coated mesh is projected to reach USD 3.2 billion by 2025, highlighting the increasing demand for reliable materials in various applications, from agricultural fencing to industrial uses.

To identify trustworthy suppliers, look for established companies with industry certifications such as ISO 9001, which indicate a commitment to quality management systems. Furthermore, transparency in their sourcing of raw materials and manufacturing processes is essential; this not only reflects their ethical standards but also guarantees a consistent product. A survey conducted by MarketsandMarkets reveals that companies prioritizing sustainability are more likely to provide high-quality PVC products, thus influencing buyers to research their suppliers thoroughly. Engaging with manufacturers who showcase testimonials and case studies can further validate their reputation, ensuring you select the best PVC coated welded mesh for your project needs.