Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

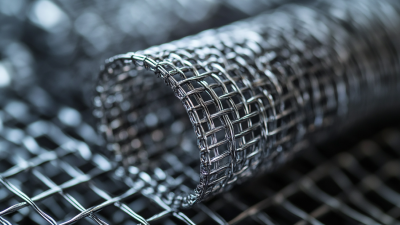

In today's manufacturing and construction industries, the demand for durable and versatile materials has propelled the adoption of Stainless Crimped Wire Mesh. According to a report by Grand View Research, the global wire mesh market size was valued at over $8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. This surge in popularity is attributed to the numerous benefits that Stainless Crimped Wire Mesh offers across various applications, ranging from filtration and safety to architectural elements. Its unique combination of strength, flexibility, and corrosion resistance makes it an ideal choice for both industrial and decorative purposes. In this blog, we will explore seven essential benefits of using Stainless Crimped Wire Mesh for your projects, highlighting why it has become a preferred material among professionals in the field.

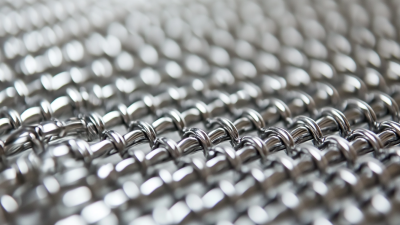

Stainless crimped wire mesh is increasingly recognized in various industries for its exceptional corrosion resistance, making it an invaluable material for long-term projects. According to a report by Grand View Research, the global wire mesh market is expected to reach USD 9.35 billion by 2025, driven largely by the construction and automotive industries' demand for durable materials. Stainless steel, particularly grades like 304 and 316, offers superior resistance to oxidation and corrosion, extending the lifespan of the mesh and reducing maintenance costs. This longevity is crucial for projects exposed to harsh environmental conditions, as corrosion can lead to structural failures and increased operational downtime.

Moreover, industry studies indicate that stainless crimped wire mesh maintains its integrity even in extreme temperature environments, further enhancing its versatility. A survey conducted by IBISWorld revealed that manufacturers and builders favor stainless steel for its ability to resist rust and pitting, particularly in coastal regions where salt exposure is prevalent. This resistance not only protects the structural elements but also ensures a cleaner appearance over time, contributing to the aesthetic appeal of installations. The combination of these benefits positions stainless crimped wire mesh as a smart investment for projects seeking durability and reliability.

Stainless crimped wire mesh offers enhanced durability that is essential for the long-term viability of various projects. Its resilience against corrosion and wear is vital in maintaining structural integrity over time. Reports indicate that the longevity of materials in construction significantly impacts economic viability. For instance, incorporating durable materials like stainless steel in construction can reduce maintenance costs by up to 30%, supporting a more sustainable approach to project management. This aspect of durability is particularly crucial in sectors facing harsh environmental conditions, where traditional materials often fail prematurely.

Stainless crimped wire mesh offers enhanced durability that is essential for the long-term viability of various projects. Its resilience against corrosion and wear is vital in maintaining structural integrity over time. Reports indicate that the longevity of materials in construction significantly impacts economic viability. For instance, incorporating durable materials like stainless steel in construction can reduce maintenance costs by up to 30%, supporting a more sustainable approach to project management. This aspect of durability is particularly crucial in sectors facing harsh environmental conditions, where traditional materials often fail prematurely.

Moreover, as industries move towards sustainable practices, the focus on utilizing materials that ensure durability aligns with broader environmental goals. Recent studies in the construction sector emphasize how sustainable supply chain management can enhance project performance while incorporating durable materials. By integrating stainless crimped wire mesh into projects, businesses can not only enhance structural longevity but also contribute positively to the circular economy. This blend of resilience and sustainability positions stainless crimped wire mesh as a keystone material for future-oriented projects, echoing the principles outlined in a review of advancing the hydrogen production economy, where technological advancements strive for both sustainability and economic efficiency.

Stainless crimped wire mesh is increasingly recognized for its versatility across a range of industries and environments. This adaptable material can be found in applications from construction to agriculture, showcasing its capability to meet diverse operational demands. Its design allows for efficient filtration and separation processes, making it particularly valuable in sectors that require precise material handling and environmental management. As industries strive to comply with stringent regulations regarding waste processing and material utilization, stainless crimped wire mesh stands out as a practical solution.

Moreover, this wire mesh plays a pivotal role in sustainability efforts across different fields. With its durable structure, it is often employed in projects aimed at biomass valorization and the remediation of environmental contaminants. By providing reliable support in various industrial applications, such as in the advancement of photocatalytic technologies and other innovative processes, stainless crimped wire mesh contributes significantly to energy conversion and the reduction of environmental impact. Its versatility ensures that it remains an essential tool for modern projects that prioritize efficiency, safety, and environmental stewardship.

Stainless crimped wire mesh offers numerous advantages, particularly when it comes to enhancing safety and security features in various projects. Its sturdy construction provides a reliable barrier against intruders and unwarranted access, making it an ideal choice for fencing solutions around residential, commercial, and industrial properties. The resistance of stainless steel to rust and corrosion further ensures longevity, meaning that maintenance efforts can be significantly reduced without compromising safety.

When selecting stainless crimped wire mesh, consider the placement and gauge of the mesh. A tighter weave can deter small animals and potential threats more effectively. Additionally, opt for a higher gauge wire for areas that require extra strength, such as perimeter fences or security cages. This simple tip can enhance the security of your property while providing peace of mind.

Another important aspect to remember is the aesthetic appeal of stainless crimped wire mesh. Not only does it secure your space, but it can also be designed to blend with the surrounding environment. Choosing a finish that complements your architecture can improve visual appeal without sacrificing safety. Therefore, when implementing stainless crimped wire mesh in your projects, focus on both security functionality and the complimentary design.

When it comes to project planning, cost-effectiveness is often a top priority. Utilizing stainless crimped wire mesh can provide significant long-term savings, making it a smart investment. Unlike other materials that may require frequent replacement or extensive upkeep, stainless steel is known for its durability and resilience. This mesh thrives in various environments, whether exposed to harsh weather conditions or corrosive substances, ensuring that maintenance requirements are minimal over time.

Additionally, the longevity of stainless crimped wire mesh reduces the frequency and cost associated with repairs or replacements. Businesses and individuals alike can benefit from the peace of mind that comes with knowing their investment is protected. With minimal maintenance needs, resources can be reallocated to other essential areas, enhancing overall project efficiency and financial health. As a result, choosing stainless crimped wire mesh not only proves beneficial in terms of durability but also leads to substantial long-term cost savings.

This chart illustrates the long-term savings associated with the use of stainless crimped wire mesh in various projects compared to alternative materials, emphasizing the minimal maintenance required over time.