Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

The selection of the right material is crucial for any project, particularly when it involves its structural integrity and longevity.

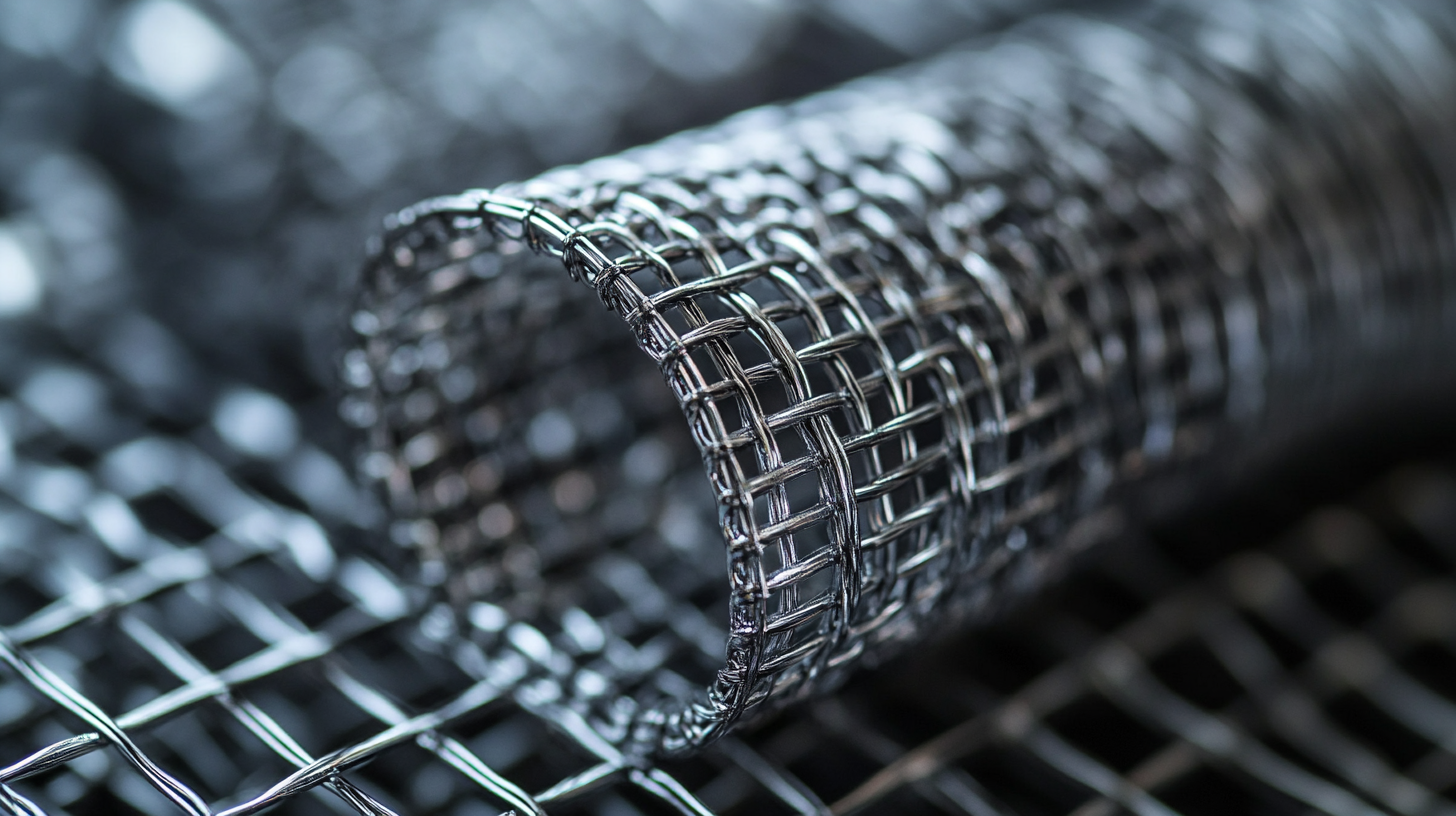

In recent years, the use of Stainless Crimped Wire Mesh has gained significant traction across various industries due to its exceptional durability and versatility.

According to a report by MarketsandMarkets, the global wire mesh market is projected to reach USD 39.68 billion by 2025, driven by increasing demand for stainless steel wire mesh in construction, agriculture, and mining sectors.

Stainless Crimped Wire Mesh, known for its resistance to corrosion and ability to withstand harsh environmental conditions, plays a pivotal role in these applications.

As industries seek high-quality manufacturing partners, sourcing from renowned hubs like China ensures access to premium products that meet global standards.

This blog aims to guide you through the essential factors in choosing the best Stainless Crimped Wire Mesh for your specific project needs.

When selecting stainless crimped wire mesh for your project, several factors are crucial to ensure optimal performance and durability. First, consider the wire diameter and mesh opening size. According to a report by the Industrial Wire Mesh Association, the right balance between these elements can significantly impact filtration efficiency and structural integrity. Selecting a wire diameter that withstands environmental stressors while providing adequate openings for your application can enhance both functionality and longevity.

Another key factor is the type of stainless steel used in the mesh. A study by the International Stainless Steel Forum highlights that different grades, such as 304 or 316, offer varying levels of corrosion resistance and strength. For projects exposed to harsh chemicals or saline environments, 316 stainless steel is often recommended due to its superior resistance to corrosion. This choice not only extends the life of the mesh but also minimizes maintenance costs over time. Always assess the specific conditions your wire mesh will face to ensure you select the most appropriate material for your needs.

When selecting stainless steel wire mesh for your project, understanding the various types of stainless steel available is crucial. The most commonly used stainless steel alloys are 304 and 316, each with unique properties that suit different applications.

304 stainless steel is widely recognized for its excellent corrosion resistance and versatility. It is ideal for indoor use and many outdoor applications in mild environments. However, for projects exposed to harsher conditions, such as saltwater or chemical environments, 316 stainless steel is generally the better choice due to its higher resistance to corrosion.

**Tips:** When choosing between these types, consider the environment of your project. If you are working near the coast or in a chemically aggressive atmosphere, always opt for 316 stainless steel for long-lasting durability. Additionally, pay attention to the wire mesh's weave type; tighter weaves may offer better filtration but could limit airflow. Remember to evaluate the mesh's aperture size based on your project's specific requirements, ensuring you strike a balance between strength and functionality.

| Mesh Type | Stainless Steel Grade | Applications | Wire Diameter (mm) | Opening Size (mm) | Aperture Type |

|---|---|---|---|---|---|

| Plain Weave | 304 | Food Processing, Filtration | 0.5 - 2.0 | 1.0 - 10.0 | Square |

| Twill Weave | 316 | Chemical Processing, Marine Applications | 0.7 - 2.5 | 0.8 - 8.0 | Rectangular |

| Dutch Weave | 304L | Water Filtration, Oil Sands | 0.4 - 1.8 | 0.5 - 5.0 | Mixed |

| Crimped Wire Mesh | 201 | Screening, Heavy Duty Applications | 1.0 - 3.0 | 10.0 - 50.0 | Square |

Stainless crimped wire mesh is a versatile material used across various industries due to its durability and resistance to corrosion. In the construction industry, it is often used for reinforcement in concrete applications, ensuring structural integrity while allowing for efficient drainage. Additionally, it serves as effective scaffolding support, providing a reliable framework for safety during building projects. The mesh's strength makes it an ideal choice for applications where extra support is critical.

In the agricultural sector, stainless crimped wire mesh finds its place in fencing and animal enclosures. Its durability protects livestock from external threats while allowing for ample ventilation. Furthermore, in the food processing industry, this mesh is commonly used in sieves and filters, ensuring that products are processed without contamination. Its hygienic properties and ease of cleaning make it suitable for environments that demand high standards of sanitation, proving its vital role in maintaining product quality and safety.

When selecting stainless crimped wire mesh for your project, understanding the quality standards in its manufacturing process is crucial. The quality of the wire mesh is largely determined by the materials used and the production techniques employed. High-quality stainless steel should exhibit excellent corrosion resistance, tensile strength, and durability. It's essential to ensure that the mesh adheres to established industry specifications, such as ASTM or ISO guidelines, which can serve as a benchmark for quality assurance.

When selecting stainless crimped wire mesh for your project, understanding the quality standards in its manufacturing process is crucial. The quality of the wire mesh is largely determined by the materials used and the production techniques employed. High-quality stainless steel should exhibit excellent corrosion resistance, tensile strength, and durability. It's essential to ensure that the mesh adheres to established industry specifications, such as ASTM or ISO guidelines, which can serve as a benchmark for quality assurance.

Further evaluation should involve the mesh design and crimping technique, as these aspects directly influence the performance and longevity of the product. Pay attention to the uniformity of wire spacing and the integrity of the crimped joints, as these are indicators of the manufacturer's commitment to quality. Additionally, consider sourcing from reputable suppliers known for their stringent quality control processes and certifications. By focusing on these quality standards, you can ensure that your stainless wire mesh will meet the demands of your specific application, enhancing both its functionality and lifespan.

When sourcing high-quality stainless crimped wire mesh from China, it's essential to understand both the market landscape and the specific qualities that can distinguish premium products. With over 300 manufacturers of high-voltage connectors in China, the country has established itself as a leading hub for various industrial materials, including wire mesh. More than 80 percent of these manufacturers are domestically owned, which can significantly affect the quality and sourcing strategies available to international buyers.

To ensure you make the right choice, consider the following tips: First, always request certifications or test reports showing compliance with international standards. Quality assurance is crucial in avoiding inferior products that do not meet your project’s requirements. Second, assess the supplier's experience in the industry—established suppliers will likely have a track record of reliability and high standards. Finally, don't hesitate to request samples before making a bulk order; this will allow you to evaluate the mesh's durability and suitability for your specific application.

Investing time in researching the market and establishing relationships with reputable suppliers in China can pay off in the long run, leading to successful project outcomes and optimal performance from the stainless crimped wire mesh you choose.

This chart illustrates the distribution of suppliers based on the quality of stainless crimped wire mesh. The data shows that there are a total of 27 suppliers, with the majority offering medium quality products, followed by low quality and then high quality options.