Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

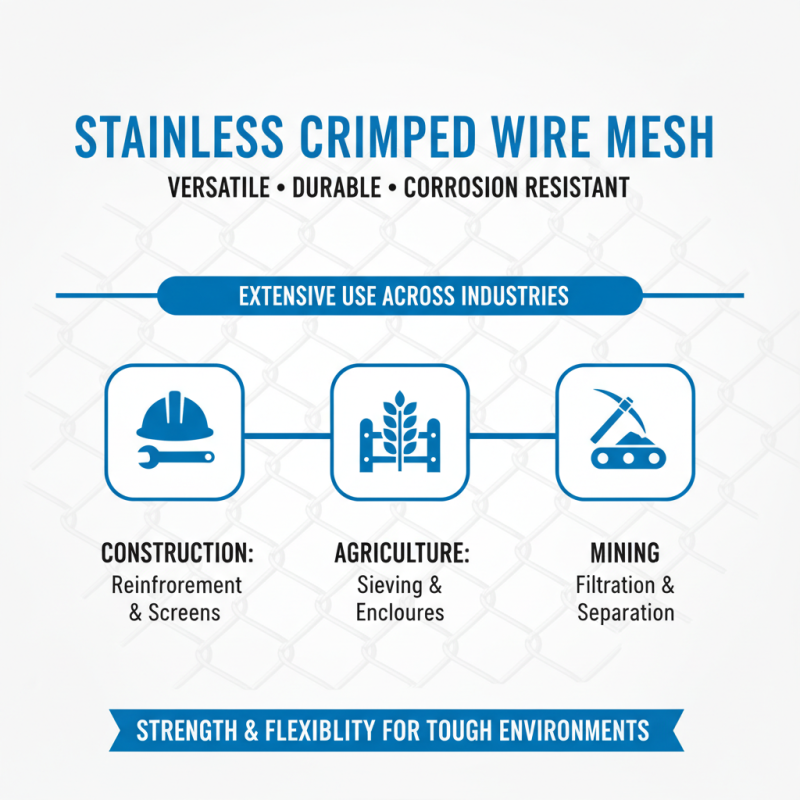

Stainless Crimped Wire Mesh has become a popular choice across multiple industries. With a growing demand for durable and versatile materials, projections suggest that the market for such mesh could exceed $1 billion by 2026. The mesh is widely used in filtration, construction, agriculture, and mining. Its ability to withstand harsh environments makes it a reliable option. According to a recent industry report, over 40% of companies in the construction sector have adopted stainless crimped wire mesh for safety and efficiency.

Additionally, the benefits extend beyond mere durability. The mesh offers excellent corrosion resistance, enhancing its lifespan significantly. Many manufacturers are implementing advancements in production techniques to improve quality and performance. However, challenges still exist in sourcing raw materials and maintaining price stability. As industries evolve, the need for innovation in stainless crimped wire mesh is crucial. It sparks reflections on how we can sustainably balance quality and cost-effectiveness.

In tackling these challenges, it is essential to acknowledge that not all products meet the high standards. Some inconsistencies in mesh specifications can lead to performance issues. Striving for improvement in manufacturing practices can bridge these gaps and ensure better customer satisfaction.

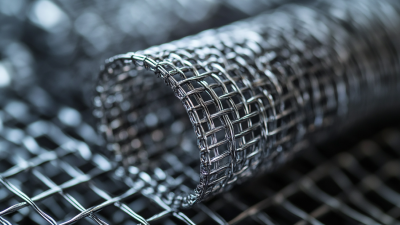

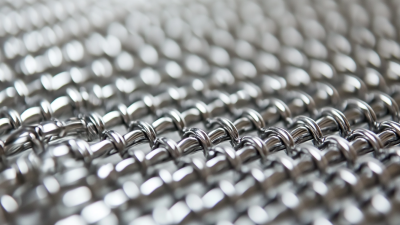

Stainless crimped wire mesh is renowned for its durability and versatility. Made from high-quality stainless steel, it is resistant to corrosion and rust. This makes it ideal for various applications in industries such as construction, agriculture, and mining. Its strength is a significant characteristic. The wires are tightly woven, providing excellent support and protection.

Another key feature of stainless crimped wire mesh is its flexibility in design. It can be customized to fit specific needs, allowing for different mesh sizes and configurations. This adaptability is crucial in environments where unique challenges arise. For instance, a tighter mesh may be needed to contain small particles, while a looser weave can allow for airflow and drainage.

However, despite its many advantages, there are drawbacks to consider. The cost can be higher than other materials. This may deter some users from choosing stainless crimped wire mesh. Additionally, it can lose its integrity if subjected to extreme conditions over time. Balancing its benefits with these limitations is essential for optimal usage.

Stainless crimped wire mesh finds extensive use across various industries. Its versatility stems from durability and resistance to corrosion. Many industries, such as construction, agriculture, and mining, benefit from this material's strength and flexibility.

In construction, crimped wire mesh is popular for reinforcing concrete structures. Data shows that using this mesh can enhance the longevity of buildings by 20%. In agriculture, it serves as fencing, protecting crops from animals. Its robust design ensures a long-lasting barrier.

Tip: Always consider the mesh size and wire thickness when choosing crimped wire mesh for specific applications. Using the wrong specifications may lead to inadequate protection or structural failure.

In the mining sector, stainless crimped wire mesh is essential for separating materials. It ensures efficient mineral extraction, enhancing productivity. Reports indicate that the right mesh can increase separation efficiency by 30%.

Tip: Regularly inspect the mesh for signs of wear. Neglecting maintenance can lead to costly downtime.

While stainless crimped wire mesh offers numerous benefits, it’s important to assess your needs thoroughly. Not every mesh type suits all purposes, and the wrong choice may impact performance.

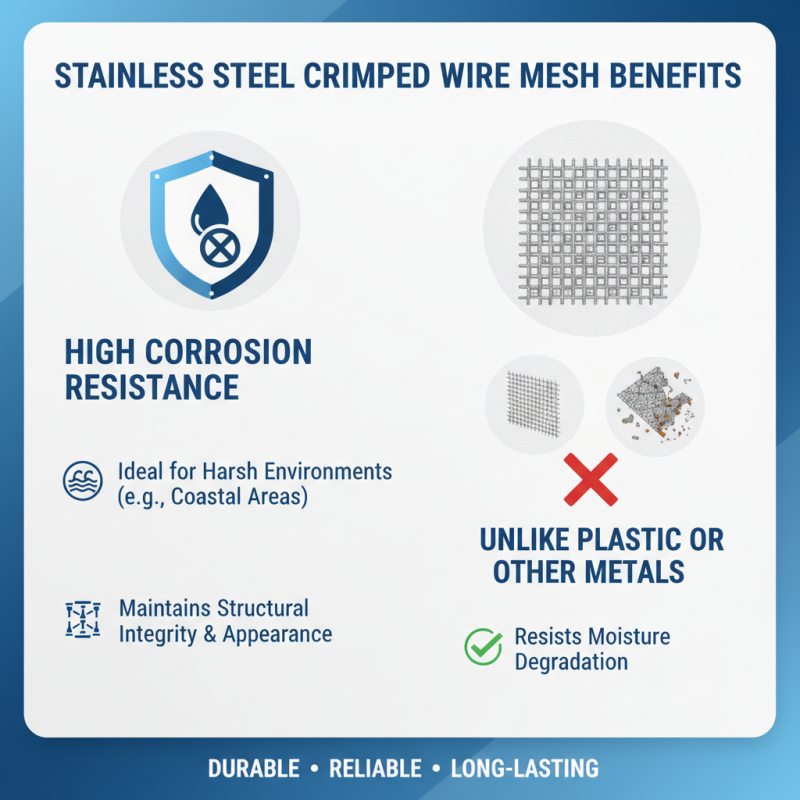

Stainless crimped wire mesh offers several advantages over other materials. One notable benefit is its high resistance to rust and corrosion. This makes it ideal for harsh environments, like coastal areas. In these conditions, it maintains structural integrity and appearance. Unlike plastic or other metals, it does not degrade when exposed to moisture.

Durability sets stainless crimped wire mesh apart. It withstands physical stress better than many alternative materials. For instance, in construction or industrial settings, it remains intact despite heavy loads. It is also easy to clean and maintain, which saves time. Users often find the installation process straightforward, requiring minimal tools.

A drawback to consider is the initial cost. Stainless steel can be more expensive than some other materials. However, its long-term benefits often outweigh this. Users should weigh the upfront cost against the longevity and durability. Ultimately, the right choice depends on specific needs and budget constraints.

Maintaining stainless crimped wire mesh products is crucial for longevity and performance. Regular checks help identify issues early. A 2022 industry report suggested that improper maintenance can reduce lifespan by up to 30%. Such products are often used in construction, agriculture, and filtration applications, highlighting the need for effective upkeep.

Cleanliness is essential. Dust and debris can accumulate and compromise the mesh’s integrity. A simple wash with water and mild detergent can work wonders. Industry experts recommend cleaning every six months, depending on environmental conditions. If neglected, corrosion-related issues can arise, especially in humid areas.

Visual inspections should be routine. Look for signs of wear, such as loose wires or bends. A small issue can escalate if left unchecked. Surprisingly, many users overlook this step. Regular monitoring can prevent costly replacements. Maintaining the right balance between usage and care is key.

| Use Case | Benefits | Maintenance Guidelines |

|---|---|---|

| Industrial Filtration | High corrosion resistance and durability | Regular washing to remove debris; inspect for wear. |

| Construction Reinforcement | Increases structural integrity | Check for rust; apply protective coatings as needed. |

| Agricultural Fencing | Long-lasting protection against animals | Inspect for damage and repair quickly. |

| Decorative Panels | Aesthetic appeal and functionality | Clean with mild detergents to avoid discoloration. |

| Filter Media for Water Treatment | Efficient particle separation | Flush regularly; replace when efficiency drops. |

The future of stainless crimped wire mesh is evolving rapidly. Industries are recognizing its versatile applications. With a surge in demand, the North American market alone is expected to grow by 6.5% annually until 2026. This indicates how manufacturers are innovating to meet specific needs.

Recent innovations have focused on enhancing the mesh's durability and corrosion resistance. For example, advanced coating technologies are being developed. These innovations aim to increase lifespan and efficiency in harsh environments. Yet, the high costs of these new technologies could limit their widespread adoption. Smaller businesses may find it challenging to invest.

In construction and filtration sectors, the focus is shifting towards customized solutions. Tailor-made wire mesh can improve performance across applications. However, there’s still a gap in understanding how these changes impact material sourcing. Industry data indicates that sustainable practices are not fully integrated. Progress is underway, but the path forward requires more commitment to environmental considerations.