Leave Your Message

-

Telephone

-

WeChat/ WhatsApp

-

Email

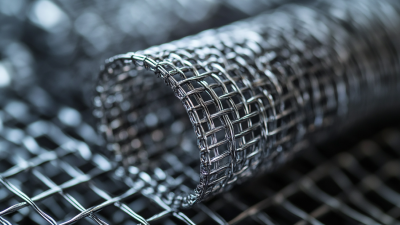

Stainless Crimped Wire Mesh has become an essential material in various industries due to its unique properties and versatile applications. Made from high-quality stainless steel, this type of wire mesh is characterized by its crimped design, which provides enhanced strength and durability. In the ever-evolving industrial landscape, understanding the benefits and uses of Stainless Crimped Wire Mesh is crucial for professionals seeking reliable and efficient solutions.

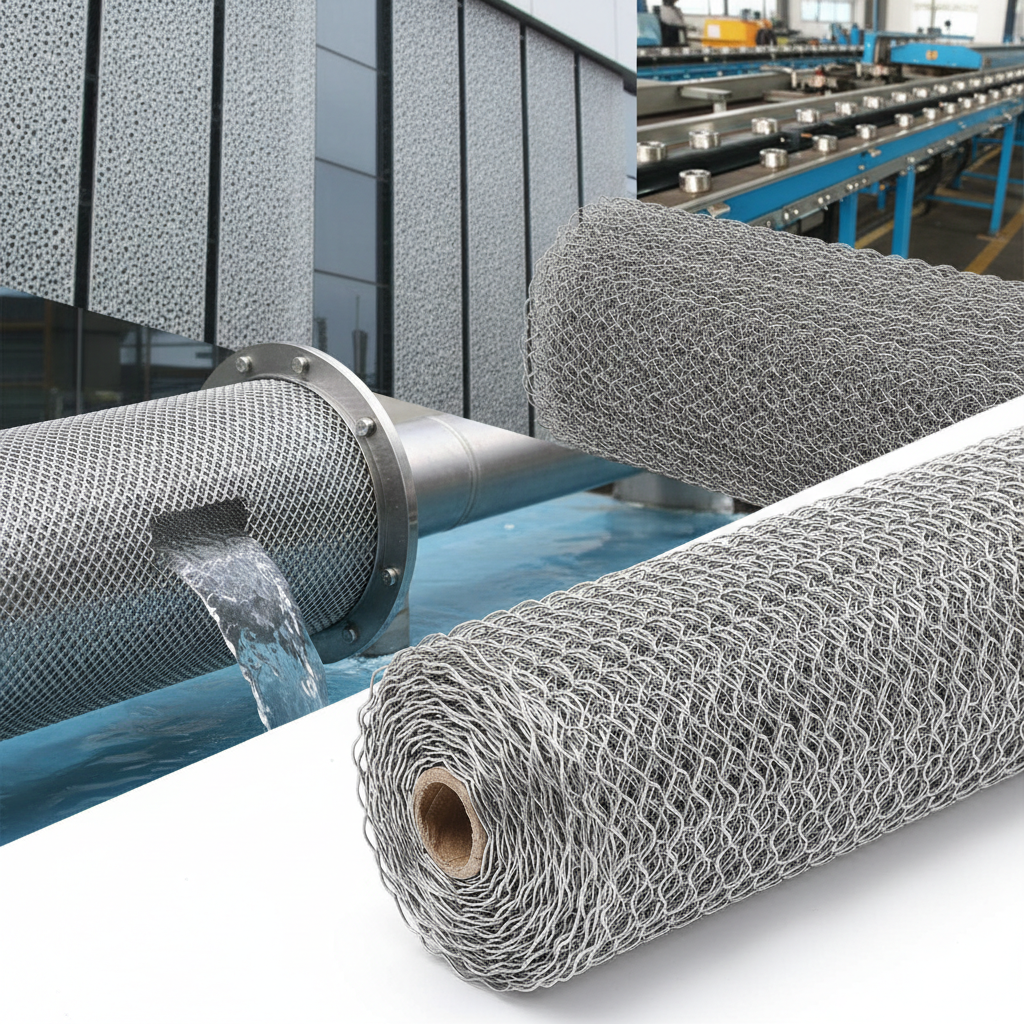

As we delve into the 2025 Guide to Stainless Crimped Wire Mesh, we'll explore its top applications across different sectors, including construction, filtration, and manufacturing. The inherent corrosion resistance and adaptability of this material make it a preferred choice for both indoor and outdoor settings. By examining the distinct advantages of Stainless Crimped Wire Mesh, readers will gain insight into how it can improve operational efficiency while ensuring safety and longevity in various projects. Whether you are a seasoned buyer or new to this material, this guide will equip you with the necessary knowledge to make informed decisions.

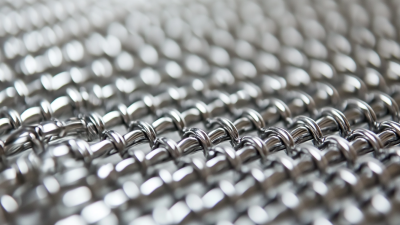

Stainless crimped wire mesh is a versatile material known for its exceptional strength, durability, and aesthetic appeal. Composed of high-quality stainless steel, this mesh is engineered through a weaving process that creates a sturdy yet flexible structure. The crimping process adds to its integrity, allowing the mesh to maintain its shape under various conditions, making it suitable for a variety of industrial and architectural applications. Its corrosion resistance ensures a long lifespan, even in harsh environments, while its open weave design allows for optimal air flow and light diffusion.

Recent architectural trends highlight the functional and attractive uses of stainless crimped wire mesh, such as in the renovation of housing. In contemporary projects, designers are incorporating this mesh into elements like sun shades and decorative facades. For instance, the recent renovation of a traditional villa in Melbourne showcases a metal-mesh curtain that elegantly wraps around an extension, providing both aesthetic value and practical protection against sunlight. This innovative use of stainless crimped wire mesh emphasizes not only its utility but also its capability to enhance the visual dynamics of modern architecture.

| Dimensional Attribute | Description | Common Uses | Benefits |

|---|---|---|---|

| Material | Stainless Steel | Architectural applications, fencing | Corrosion resistance, durability |

| Wire Diameter | Varies (commonly 0.2mm to 8mm) | Industrial screens, safety barriers | Customizable strength and flexibility |

| Mesh Size | From 1mm to 100mm openings | Filtration systems, sieves | Effective separation, easy cleaning |

| Weave Type | Square and rectangular | Cages, enclosures | Versatile use in various projects |

| Finish | Polished, mill finish | Decorative screens, partitions | Aesthetic appeal, ease of maintenance |

Stainless crimped wire mesh is a versatile material widely utilized across various industries due to its strength and durability. In the construction industry, it serves as a vital component for reinforcing concrete, enhancing the structural integrity of buildings and bridges. Additionally, it is commonly employed in architectural applications, including facades and railings, where both aesthetic appeal and safety are paramount. The mesh's corrosion resistance makes it especially suitable for outdoor settings, ensuring longevity even under harsh environmental conditions.

In the agricultural sector, stainless crimped wire mesh plays a crucial role in livestock fencing and crop protection. Its robust design prevents animal escapes while safeguarding crops from pests. Similarly, in the manufacturing and mining industries, the mesh is used for filtration and sieving processes, efficiently separating materials and maintaining product quality. With its ability to withstand high pressures and temperatures, stainless crimped wire mesh is essential for maintaining operational efficiency in these demanding environments.

Stainless crimped wire mesh is renowned for its exceptional durability and longevity, making it a preferred choice across various industries. The design of the mesh, combined with the quality of stainless steel, provides enhanced resistance to corrosion, rust, and wear. This means that structures built with crimped wire mesh can withstand harsh environmental conditions without compromising their integrity, ensuring long-term usability.

When selecting stainless crimped wire mesh for your projects, consider the specific needs of your application. For instance, a thicker wire may provide additional strength and durability, making it ideal for heavy-duty tasks. Additionally, the crimped design allows for better load distribution, which can be crucial in high-stress scenarios.

Tips: Always check the specifications for tensile strength and load capacity. Proper installation is key to maximizing the benefits of stainless crimped wire mesh; ensure that the supports are adequately placed to prevent sagging. Regular maintenance, such as cleaning and inspections, will help identify any potential issues before they become significant problems, thus extending the lifespan of your wire mesh.

Stainless crimped wire mesh offers distinct advantages over other types of wire mesh, making it a preferred material in various industries. One of the primary benefits is its corrosion resistance, which surpasses ordinary steel and is comparable to other stainless steel products. According to a report by the International Stainless Steel Forum, over 70% of stainless steel is used in applications demanding high corrosion resistance, reflecting the increasing demand for durable materials. Additionally, stainless crimped wire mesh provides strength and stability, making it suitable for applications in construction, agriculture, and mining.

When comparing stainless crimped wire mesh to alternatives like aluminum and plain steel mesh, the former exhibits superior longevity and performance under adverse conditions. While aluminum is lightweight and resistant to corrosion, it lacks the strength required for heavy-duty applications. Conversely, plain steel mesh may be cost-effective, but its susceptibility to rust makes it less desirable in environments exposed to moisture. A survey from the Wire Reinforcement Institute indicates that users prioritize durability and lifespan, with 85% opting for stainless materials over alternatives for critical applications.

**Tips:** When selecting wire mesh for your project, consider the specific environmental conditions it will face. For high-corrosion areas, stainless crimped wire mesh is often the best option. Furthermore, always verify the specifications and certifications of the mesh to ensure it meets your industry standards for quality and safety.

When installing stainless crimped wire mesh, it is crucial to follow best practices to ensure longevity and functionality. First, proper site preparation is essential. The installation area should be cleared of debris, and the frame or support structure must be sturdy and level to prevent any misalignment during installation. Additionally, selecting the appropriate mesh size and wire gauge based on your specific application needs will enhance the performance and durability of the mesh.

Routine maintenance is equally important to maximize the lifespan of stainless crimped wire mesh. Regular inspections should be conducted to identify any signs of wear, corrosion, or damage. Cleaning the mesh periodically with non-abrasive solutions will help maintain its appearance and structural integrity. Furthermore, applying protective coatings when necessary can provide an additional layer of defense against environmental factors. Following these best practices will ensure that your stainless crimped wire mesh remains effective and aesthetically pleasing for years to come.

This chart illustrates the various applications of stainless crimped wire mesh in different industries for 2025. The data indicates that construction is the leading sector for its use, followed by filtration and food processing.