Rockfall Barrier System Slope protection Hillside Stabilization

products specification

| Material | High carbon steel wire. |

| Surface treatment | Hot dipped galvanized, zinc-aluminum coated. |

| Zinc thickness | No less than 150 g/m². |

| Wire diameter | 3 mm, 4 mm. |

| Mesh type | Rhomboid hole. |

| Mesh size | 65 mm inscribed circle diameter. |

| Tensile strength | Minimum 1770 MPa. |

| Braking load of single wire | 12.5 kN. |

| Mesh roll width | 1–3.5 m. |

| Mesh roll length | 10–30 m. |

| Fitting | Steel anchor, claw type spike plate, soil or rock nails, clips, sewing rope, boundary rope. (The steel anchor is made of deformed steel bar of 25 mm diameter) |

Product Advantages

• It utilizes corrosion processes such as zinc dipping, alloying, and galfan, thereby improving corrosion resistance and extending the system's lifespan;

• The system exhibits superior connectivity, reducing component damage rates by 80% after impact;

• With modular unit design, installation and maintenance are more convenient, resulting in low maintenance costs and high cost effectiveness;

• All products are designed and produced following the JT/T1328-2020 standard, and they have passed rockfall impact tests in accordance with the TB/T3449-2016 standard, receiving a Grade A evaluation.

Product description

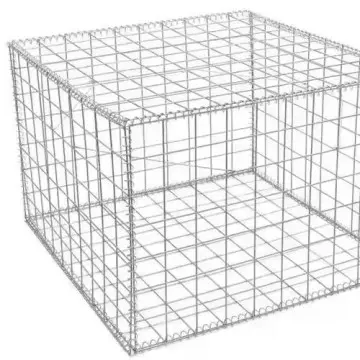

Passive protection mesh is a kind of slope protection structure, mainly composed of wire rope net, ring net, fixing system, vacuum ring and steel column . The following is a detailed introduction to the passive protective net:

Composition: The passive protective network is composed of four main parts: wire rope net or ring net, fixing system (including anchor rod, anchor rope, base and support rope), decompression ring and steel column.

Function: the combination of steel column and steel wire rope net constitutes a whole, forming surface protection for the protected area, thereby preventing the collapse of rock and soil mass from falling, and playing the role of slope protection.

Features: passive protective net has high flexibility, high protection strength, easy to spread, can adapt to complex terrain, and the installation procedure is standardized and systematic. Its special manufacturing process and high anti-corrosion surface treatment technology determine the ultra-high life of the system.

Application: Passive protective net is widely used in high mountains with buffer zone next to building facilities to stop natural disasters such as rockfall, flying rocks, avalanches, debris flows and so on, and protect building facilities from damage.

Installation method of passive protective mesh

1.Preliminary preparation:

Clean slopes and remove pumice and overburden.

Prepare tools and materials, including fasteners such as screws and bolts, protective mesh, and columns.

2.Measurement and positioning:

Measure and mark the position of bolt and base according to the design drawing.

Measure and mark the location for installation of protective mesh.

3.Mounting base and column:

Use a hand drill to drill holes at marked locations, fill grout, install base and anchor.

Use screws or bolts to secure the post to the marked position, ensuring that it is secure and vertical.

4. Install protective mesh:

Spread the protective mesh on the column and fix it with fasteners to ensure that it is smooth and without gap. Lay wire rope net and grid mesh, and sew together 1 with steel rope.

5. Check and test:

After the installation is complete, check whether the connection is firm and the protective mesh is intact.